What It Does

Powers the elevator for an extended number of trips, ensuring the complete evacuation of a building.

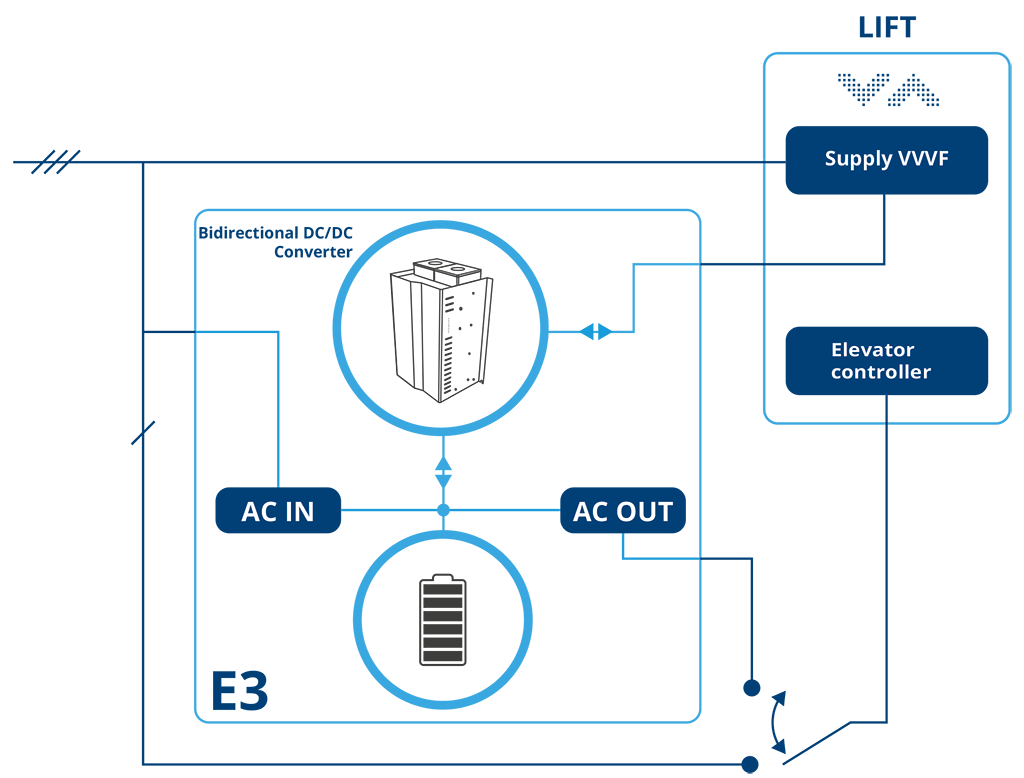

The E3 system guarantees the operation of the elevator during multiple trips in case of power failure, allowing the complete evacuation of the building without altering the normal operation of the lift controller. It uses and stores the energy generated by the elevator itself to provide a high-performance auxiliary power supply, without the need for external generators or additional systems.

In addition, the system communicates constantly and easily with the lift controller to report the state of charge of the batteries, ensuring total control at all times.

- Easy integration with the lift controller

- Valid for both new and existing elevators

- Scalable for any load, installation stroke and rated speed

- Replaces diesel generators and general-use UPS systems

- Optimized solution to adapt to the actual elevator requirements, avoiding oversizing.

- Complies with key standards such as EN81-72, EN81-76 and BS9999 for evacuation and fire protection

- Uses 48 V batteries, economical, easy to replace and very compact in volume, but specific to the evacuation application.

- Recovers the energy generated during elevator operation, extending the autonomy during evacuation

- The batteries are subjected to small, fully automatic daily cycles to ensure proper maintenance, allowing easy monitoring of the batteries.

- Solution adaptable to both machine room and machine roomless elevators

How It Works

High-performance auxiliary power supply for elevators in case of power failure

- The solution uses cost-effective, small-volume 48 V batteries designed specifically for emergency applications. It provides a reliable and easily maintainable backup system to ensure evacuation in any situation.

- Compatible with any new or existing elevator

- In emergencies, the system provides full auxiliary power supply to the switchgear and drive, ensuring a safe and controlled evacuation. It informs the controller of the state of charge of the batteries throughout the process.

Case studies

Case Study 1

Hospital

| Maximum load [kg]. | 630 |

| Total travel distance [m] | 3,9 |

| Evacuation velocity [m/s]. | 1 |

| Evacuation time [h] | 0,25 |

| Travel during evacuation | 150 |

| SOLUTION | e3 5k5 M 74Ah |

Case Study 2

Offices

| Maximum load [kg]. | 450 |

| Total travel distance [m] | 59 |

| Evacuation velocity [m/s]. | 1,05 |

| Evacuation time [h] | 2 |

| Travel during evacuation | 178 |

| SOLUTION | e3 3k5 2xL 105Ah |

Case Study 3

Residence

| Maximum load [kg]. | 1125 |

| Total travel distance [m] | 11 |

| Evacuation velocity [m/s]. | 0,63 |

| Evacuation time [h] | 2 |

| Travel during evacuation | 144 |

| SOLUTION | E3 YK 2Xl 105aH |

TECHNICAL SPECIFICATIONS

The system consists of:

A 500W single-phase input.

Two power output connections:

- 230Vac to power the control panel, brakes, lighting, etc.

- 600Vdc to power the variable speed drive.

Battery kit

Battery kit specifically designed for uninterruptible power supply systems.

| e³3k5 | e³5k5 | e³7k | e³11k | e³XXk | |

|---|---|---|---|---|---|

| Maximum input power | 450 W or 750 W | 450 W or 750 W | 900 W or 1500 W | 900 W or 1500 W | xx W (as required) |

| Nominal output power (inverter) | 3500 W | 5500 W | 7000 W | 11000 W | xxxxx W |

| Maximum output power (inverter) | 4200 W | 7000 W | 8400 W | 14000 W | 1.2 x Nominal power |

| Output nominal power (maneuver) | 750 W (different options) | ||||

| Energy storage | From only 4 12V batteries | From only 4 12V batteries | From only 8 12V batteries | From only 8 12V batteries | As required (no battery limitation) |

| No. of trips after main power failure | No limitation. Based on the needs. | ||||

| No. of operating hours after main power failure | No limitation. Based on the needs. | ||||

Advice and support

We know that good technical support is key. Since our inception, we have guaranteed expert assistance in sizing, installation and after-sales, offering agile and precise answers to optimize each project.

Case studies

Integrated product

solutions

-

Emergency evacuation equipment for long distance elevator. Case study.

- Solution: e3

- North of Spain

- 450 kg

- 59m – 20 stops

-

Occupant evacuation elevators technology

- Solution: e3

- Londres

- 1350 kg.

- 7m – 2 stops

Products